- TANK AGITATOR DESIGN PORTABLE

- TANK AGITATOR DESIGN CODE

TANK AGITATOR DESIGN CODE

Our engineers, machinists and fabrication specialists routinely meet such code requirements as USFDA, BISC, ABS, API and UL as well as ASME.

Our fabrication plants are ASME code certified and can provide the ASME stamp when required.  State of the art production machinery and design facilities at each of our fabrication plants give us the control necessary to offer flexible service and air-tight quality assurance. Mechanical design does not end with the shaft, since strength and practical issues remain for the impeller. Ross builds polished vessels and reactors, pressure vessels and atmospheric tanks, columns and large diameter pipe to meet the special needs of many industries. The combination of custom process and mechanical design necessary for mixers is unique for chemical process equipment. Ross offers a combination of engineering and manufacturing resources that few fabricators can match. These stainless steel reaction vessels are available for our clients at a very conventional range of prices.The Main Fabrication and Assembly Bay located at Ross Engineering in Savannah, GA is ideal for jobs of virtually any size and complexity, Ross can deliver exactly the support you need at extremely competitive prices.ĭuring the last decade, Ross has grown to be one of the best-equipped and most highly respected custom fabricators in North America. These stainless steel reaction vessels are generally used in the chemical and pharmaceutical companies for the purpose of providing a safe and reliable facility of performing reactions.

State of the art production machinery and design facilities at each of our fabrication plants give us the control necessary to offer flexible service and air-tight quality assurance. Mechanical design does not end with the shaft, since strength and practical issues remain for the impeller. Ross builds polished vessels and reactors, pressure vessels and atmospheric tanks, columns and large diameter pipe to meet the special needs of many industries. The combination of custom process and mechanical design necessary for mixers is unique for chemical process equipment. Ross offers a combination of engineering and manufacturing resources that few fabricators can match. These stainless steel reaction vessels are available for our clients at a very conventional range of prices.The Main Fabrication and Assembly Bay located at Ross Engineering in Savannah, GA is ideal for jobs of virtually any size and complexity, Ross can deliver exactly the support you need at extremely competitive prices.ĭuring the last decade, Ross has grown to be one of the best-equipped and most highly respected custom fabricators in North America. These stainless steel reaction vessels are generally used in the chemical and pharmaceutical companies for the purpose of providing a safe and reliable facility of performing reactions.

Vertical Orientation, Horizontal Orientationīeing one of the most reliable, trusted and renowned companies of this line of work, we are providing a wide range of HighPressure Mixing Vessels. Side-entering mixers are what the name implies, mixers that enter the tank or vessel.

TANK AGITATOR DESIGN PORTABLE

(Courtesy of Lightnin.) Obviously large, custom motors would never be applied to a portable mixer, but explosion-proof motors would.

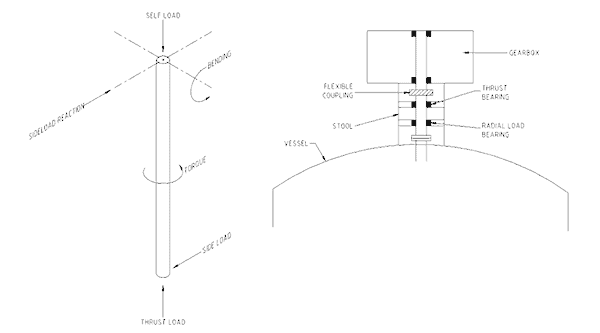

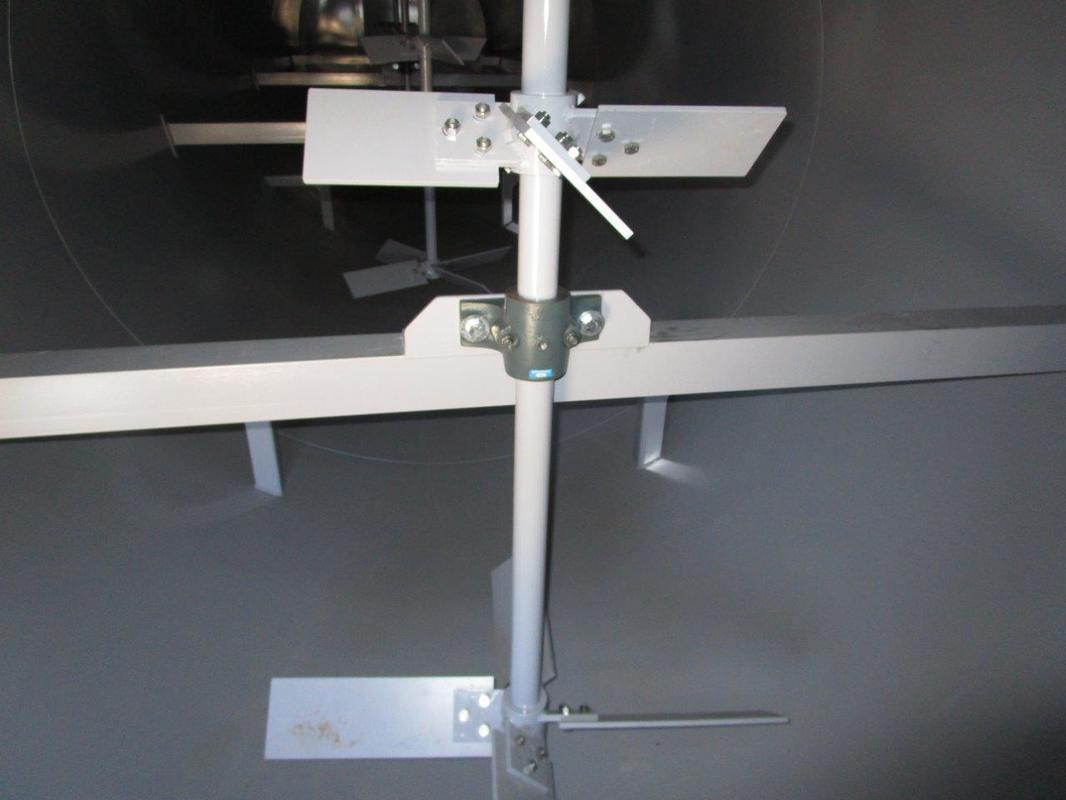

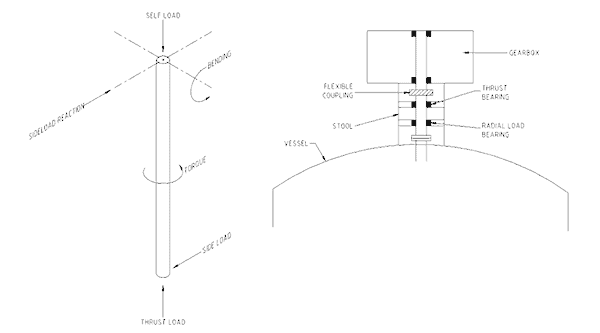

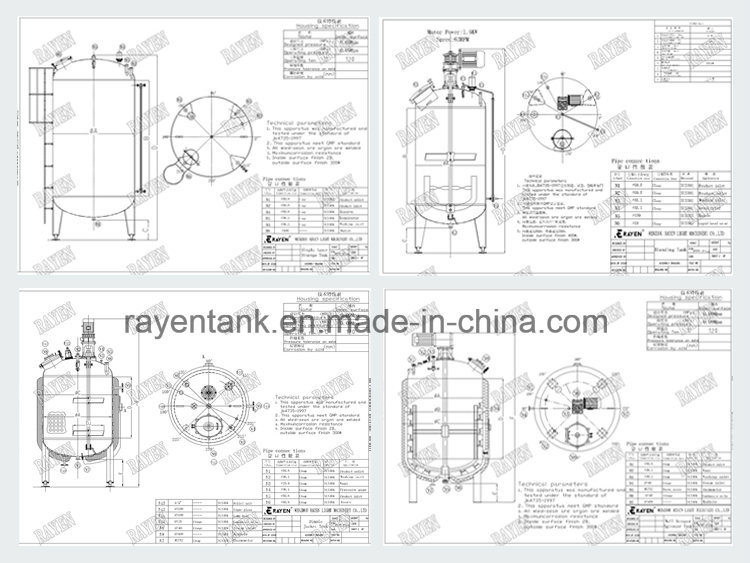

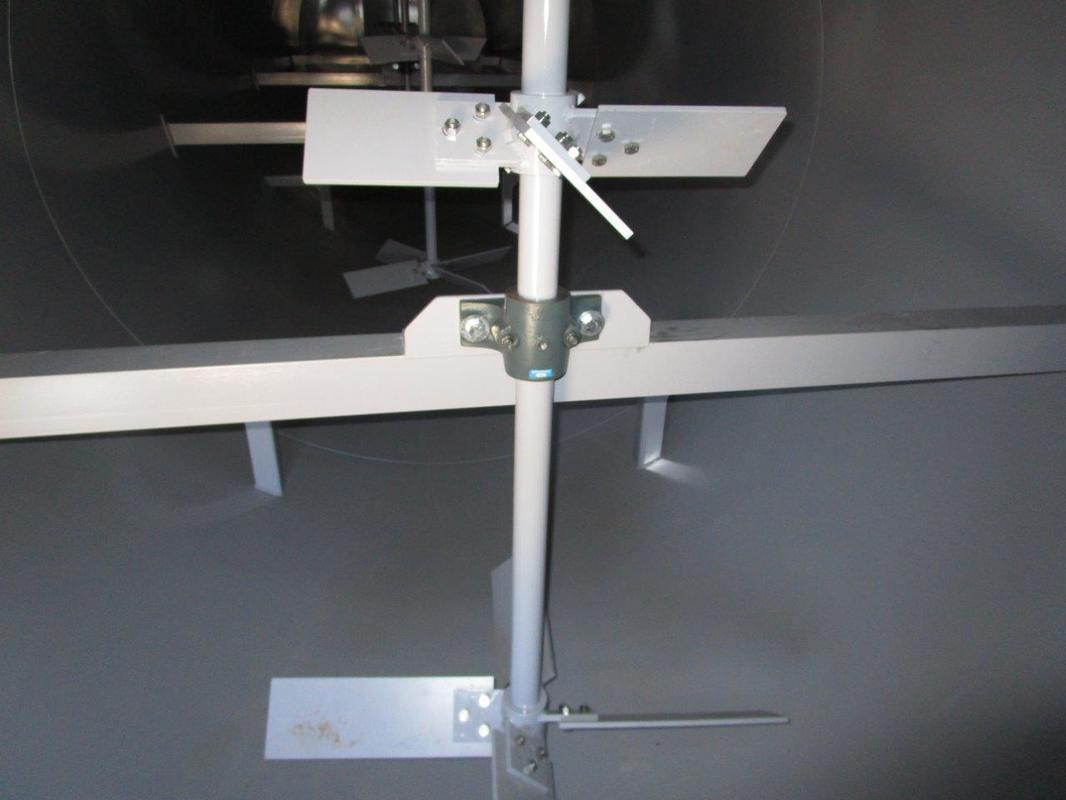

Contains reactor with agitator which is mechanically sealed 1252 MECHANICAL DESIGN OF MIXING EQUIPMENT Figure 21-3 Top-entering mixer with mechanical seal. Baffles are also provided inside the shell as per the requirement Application Industries Shaft Can fitted with different types Of Agitator Such as Single Anchor, Double Anchor, Turbine & Propeller types. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or real-world item, product, or good it may purport to portray. Top Side flat endĪgitator assembly mounted on the Top dish of Mixing Tank consists of Shaft supported by Lantern Assembly on the Top End containing Bearing Housing with Tapered roller bearing to withstand impact load and vibratory load ensuring smooth rotation of the Shaft. The Computer-Aided Design ('CAD') files and all associated content posted to this website are created, uploaded, managed and owned by third party users. Īgitator Mixing Tank consist of a Cylindrical vertical shell with standard Tori spherical/ Ellipsoidal dish on both ends.Īgitator Mixing Tank consist of a Cylindrical vertical shell with standard Tori spherical/ Ellipsoidal dish on Bottom ends. The vessel can be easily operated in batch mode with temperature going up to 150*C To 500 C Depending on the requests of the process the agitated vessel consists of unalloyed or alloyed steel. We have made the agitated Mixing tank as a standard apparatus in the chemical industry and its basic work is for mixing processes and for chemical reactions in the liquid phase.

0 kommentar(er)

0 kommentar(er)